Sheet Metal Stamping Die

We are manufacturring a variously stamping dies from 1960.(The Yamamoto MFG age is included.)

Our production die meet all customer requirement with high reliability.

We introduce our typical product.

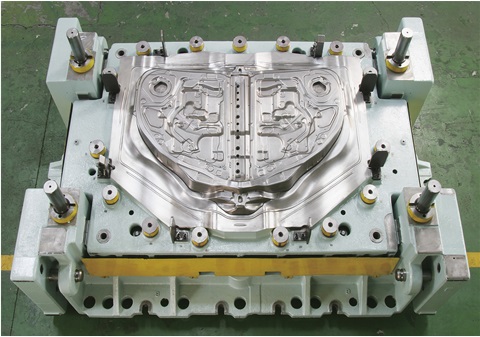

【Trim&CamPi die for Body Side Outer】 |

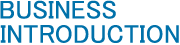

| 【Body Side Outer】 |

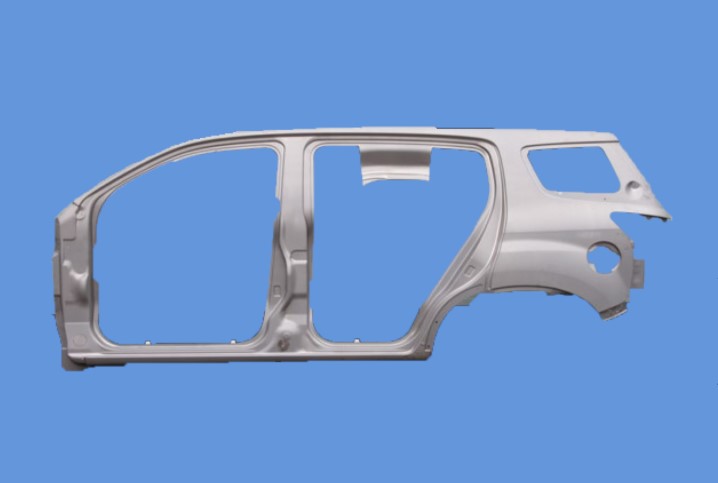

【Front Door Inner】 |

【Rear Door Outer】 |

【Floor Panel】 |

Sheet Metal Stamping Die②

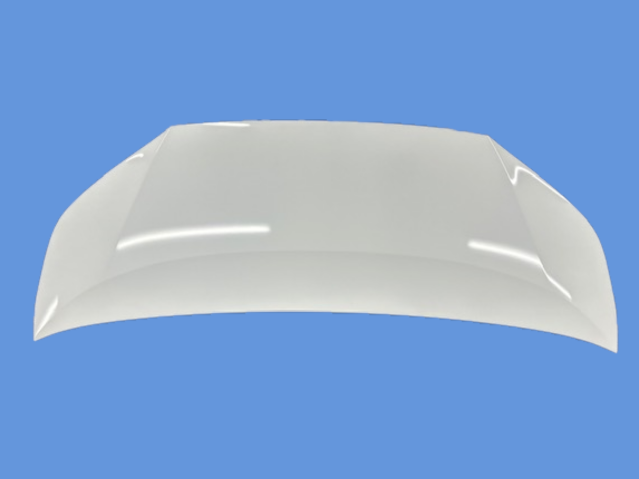

【Hood Outer】 |

【Roof Panel】 |

【Back Door Outer】 |

【Front Fender】 |

【Rear Door Outer】 |

【Side Wall Outer】 |

Press die Manufacturing process

From ability analysis

We do from simulation before Die design.

Target is the 100% panel quality at first tryout.

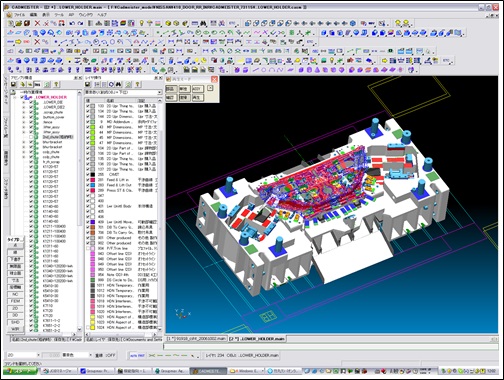

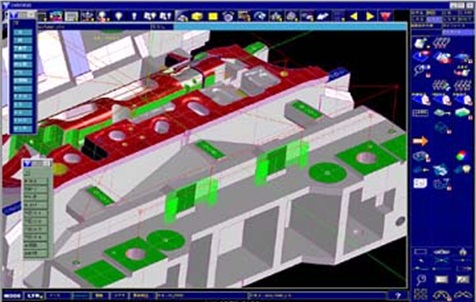

3D Solid Die design

3D solid Die design solve manufacturing problem at Die design stage.

Cam Programing

We make CAM programing for high percision machine work with good efficiency.

High precision machine work

High precision machine work in Temperature control room.

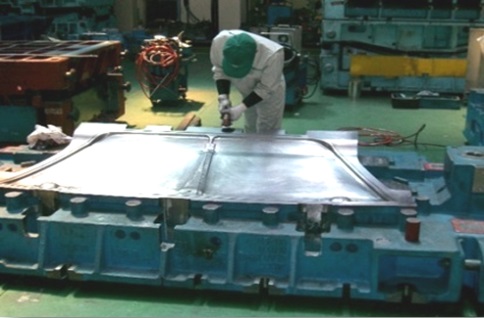

Finishing-High level final adjustment

The skilled tool maker take final fine adjustment.

Tryout

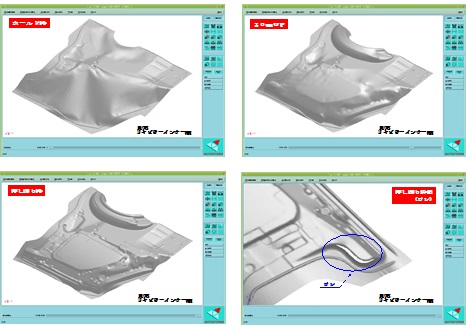

We produce first tryout panel and investigate the panel quality by shape analysis program(VECTORON).

It will be reduced the quality loop and lead time.

Inspection & Quality Analysis

Level Up

The skilled tool maker makes the die modfication with short lead time for curstomer requirement based on the modification plam.

Die Completion